Understanding Hydraulic Manual Compression Machines

Hydraulic manual compression machines are essential tools in the construction industry, designed to apply high-pressure force to materials for various construction applications. At their core, these machines use hydraulic fluid to generate force, which is then manually controlled to compress or shape materials.

Historically, hydraulic systems have evolved significantly from simple water-based mechanisms to sophisticated machines utilizing advanced fluid dynamics. Today’s hydraulic manual compression machines incorporate state-of-the-art technology to enhance efficiency and effectiveness in construction.

Key components of these machines include the hydraulic pump, pressure gauge, control valves, and the compression head. Each component plays a critical role in ensuring the machine operates smoothly and effectively under high-pressure conditions.

Benefits in Construction Projects

Using hydraulic manual compression machines in construction projects offers numerous benefits. Firstly, they significantly enhance efficiency and productivity by allowing workers to perform tasks quickly and accurately. This leads to faster project completion times and cost savings.

Secondly, these machines improve precision and quality, ensuring that materials are compressed uniformly and consistently. This is particularly important in applications where exact specifications and standards must be met.

Lastly, hydraulic manual compression machines reduce manual labor and physical strain on workers. By utilizing hydraulic force, less physical effort is required, leading to a safer and more comfortable working environment.

Choosing the Right Machine

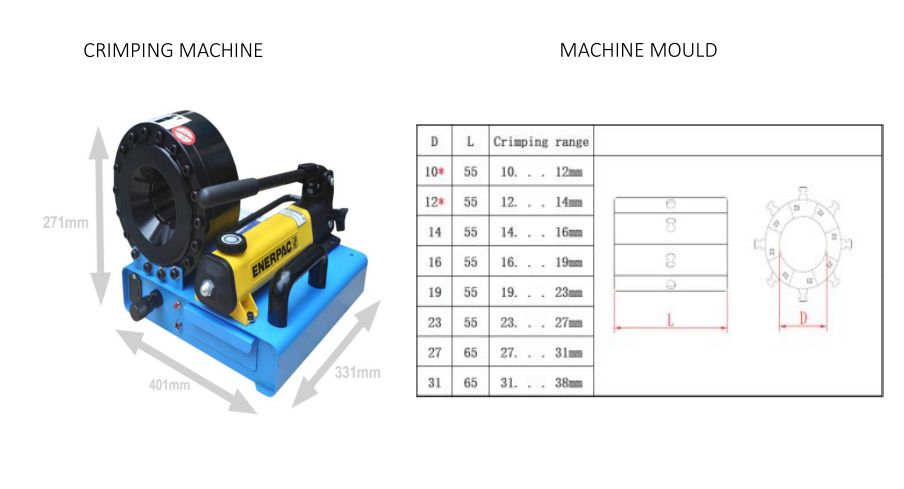

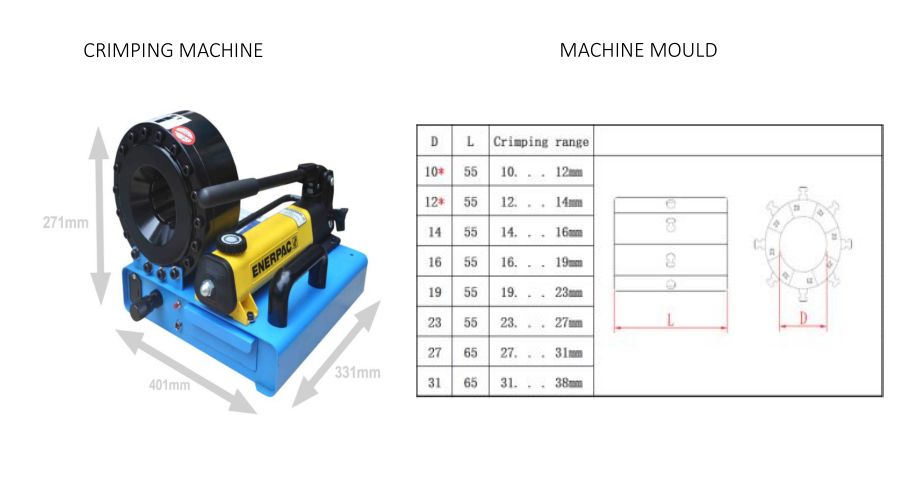

When selecting a hydraulic manual compression machine, several factors need to be considered, such as capacity, size, and portability. Capacity refers to the maximum pressure the machine can generate, while size and portability determine how easily the machine can be transported and used on-site.

Leading brands in the market include Gden Auto and Motorcycle Parts Firm, known for their high-pressure hydraulic manual compression parts. Comparing different models based on price and performance can help in making an informed decision that balances cost with functionality.

Basic Operation Techniques

Setting up a hydraulic manual compression machine involves several steps. Begin by placing the machine on a stable surface and connecting the hydraulic hoses securely. Ensure the pressure gauge is readable and all control valves are in the correct position.

Safety measures are paramount. Always wear protective gear and follow manufacturer guidelines to prevent accidents. Common mistakes, such as overloading the machine or ignoring maintenance, can lead to operational failures. Avoid these by adhering to recommended practices.

Advanced Usage Tips

To optimize performance, adjust the machine settings based on the material being compressed. Different materials require varying pressure levels and compression techniques. Regular maintenance, including checking hydraulic fluid levels and inspecting components for wear, ensures longevity.

If issues arise, troubleshooting common problems such as pressure drops or leaks can prevent downtime. Refer to the machine’s manual for specific troubleshooting steps and solutions.

Case Studies and Real-World Applications

Hydraulic manual compression machines have been successfully implemented in numerous large-scale construction projects. For example, a recent project utilized these machines to compress steel beams with precision, resulting in a structurally sound and aesthetically pleasing outcome.

Industry professionals often commend the reliability and efficiency of these machines. Testimonials highlight the reduced physical strain on workers and the consistent quality of work produced.

Before and after comparisons of projects show significant improvements in material handling and overall project timelines, reinforcing the value of hydraulic manual compression machines in construction.

Innovations and Future Trends

Technological advancements in hydraulic systems continue to shape the future of construction machinery. Innovations such as smart sensors and automated control systems are being integrated into hydraulic manual compression machines, enhancing their functionality and ease of use.

Looking ahead, the integration of these machines with smart construction technologies, such as IoT and AI, promises to revolutionize construction practices. Predictive maintenance and real-time performance monitoring are just a few of the advancements expected in the next decade.

Resources and Further Reading

For those interested in learning more about hydraulic manual compression machines, several resources are available. Recommended books and manuals provide in-depth knowledge and practical guidance.

Online tutorials and webinars offer visual demonstrations and expert insights, while industry forums and professional networks connect users with a community of professionals for advice and support.