Understanding High-Pressure Hydraulic Manual Compression Machines

High-pressure hydraulic manual compression machines are crucial components in the realm of construction machinery. These machines are designed to provide immense force and precision, making them indispensable for various heavy-duty applications. Unlike other hydraulic systems, high-pressure hydraulic manual compression machines offer superior control and reliability, which are essential for the demanding environment of construction sites.

Historically, hydraulic systems have evolved significantly. Early hydraulic systems were rudimentary and limited in their capabilities. Today, advancements in technology have led to the development of sophisticated high-pressure hydraulic systems that are more efficient, durable, and versatile.

Component Breakdown

High-pressure hydraulic manual compression machines are composed of several core components. Pumps, cylinders, and valves are the heart of these systems. The pump generates the hydraulic pressure needed to operate the machine, while the cylinder converts this pressure into mechanical force. Valves control the flow and direction of the hydraulic fluid.

Material specifications are critical for the durability and longevity of these machines. High-quality materials such as high-strength steel and advanced composites are commonly used. These materials ensure that the machines can withstand the harsh conditions of construction sites.

Safety features are also paramount. High-pressure hydraulic manual compression machines are equipped with overload protection and emergency controls to prevent accidents and ensure safe operation.

Mechanics and Operation

The working principle of high-pressure hydraulic systems involves converting hydraulic energy into mechanical energy. When the hydraulic fluid is pressurized by the pump, it flows through the valves and into the cylinder, causing the piston to move and generate force.

There are both manual and automated high-pressure hydraulic systems. Manual systems offer greater control and are often more affordable, but they require more physical effort. Automated systems, on the other hand, provide ease of operation and increased efficiency but come at a higher cost.

Maintenance is crucial for the longevity of these machines. Routine checks and addressing common issues such as leaks and wear can prevent major breakdowns and extend the life of the equipment.

Applications in Construction Machinery

High-pressure hydraulic manual compression machines are used in various construction applications. They are essential in heavy-duty construction tasks involving excavators, loaders, and cranes. These machines provide the force needed to lift and move heavy materials.

In precision work such as concrete pouring and road construction, these machines ensure accurate and consistent performance. They are also invaluable in specialized uses like tunneling and mining, where precision and reliability are critical.

Key Features to Look For

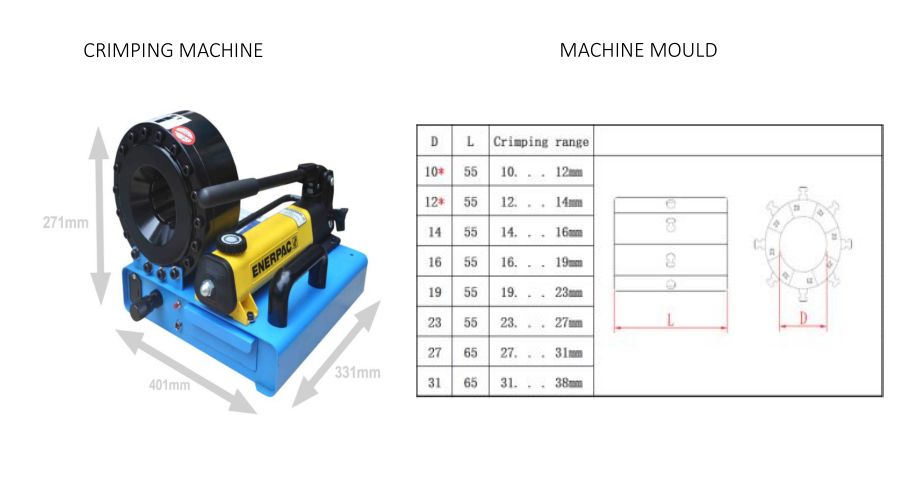

When selecting a high-pressure hydraulic manual compression machine, several key features should be considered. Pressure ratings and output capacity are crucial for ensuring the machine can handle the required tasks. Compactness and portability are also important, especially for projects that require frequent relocation of equipment.

Ease of operation and ergonomic design can enhance user comfort and reduce fatigue, making the machine more efficient and user-friendly.

Benefits and Advantages

High-pressure hydraulic manual compression machines offer numerous benefits. They increase efficiency and productivity by providing the necessary force and precision for various construction tasks. Their versatility allows them to be used in a wide range of applications, from heavy-duty lifting to delicate precision work.

In the long term, these machines are cost-effective. Their durability and reliability reduce the need for frequent replacements and repairs, leading to significant savings.

Challenges and Limitations

Despite their advantages, high-pressure hydraulic manual compression machines have some challenges. Potential technical failures can occur, but these can often be addressed with proper maintenance and timely repairs.

Environmental impact and sustainability are also concerns. Hydraulic systems can leak fluids, which may harm the environment. Using eco-friendly hydraulic fluids and implementing proper disposal methods can mitigate these issues.

Training requirements are another limitation. Proper training is essential for operators to use these machines safely and effectively.

Choosing the Right Machine

Selecting the right high-pressure hydraulic manual compression machine involves assessing project needs and machine compatibility. Comparing brands and reading reviews can provide insights into the best options available. Budget considerations are also important, balancing initial costs with long-term investment benefits.

Future Trends and Innovations

The future of high-pressure hydraulic manual compression machines is promising, with ongoing technological advancements. Integration with smart construction technologies is expected to enhance functionality and efficiency. Predictions indicate market growth and evolution, with more innovative solutions becoming available.

Expert Tips and Best Practices

Proper handling and usage techniques are essential for maximizing the efficiency and lifespan of high-pressure hydraulic manual compression machines. Regular maintenance and troubleshooting common problems can prevent costly repairs and downtimes.

For those looking to deepen their understanding, various resources are available for further learning and professional development in hydraulic systems and construction machinery.