In the modern industrial environment, high-pressure hydraulic system has become the key to improve work efficiency. The core of this technology is to accomplish tasks that are difficult to achieve by traditional methods through strong pressure output. For example, this high-pressure hydraulic manual compressor specially designed for construction machinery can convert the pressure of liquid into huge mechanical force, so as to easily solve a series of problems such as heavy parts installation and pipeline repair.

Compared with other types of compression equipment, it is unique in that it can continuously provide a stable high-pressure environment with low energy consumption. This capability makes it an ideal choice for many complex conditions, whether it is precision assembly in the factory workshop or emergency maintenance on the field site, can show excellent results.

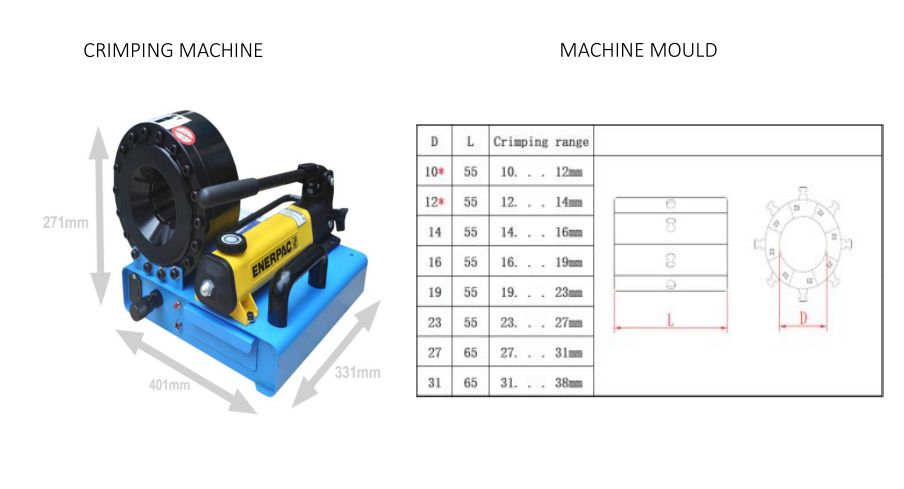

In addition to strong power support, the device also pays special attention to user-friendliness and convenience. Even people without any professional background can get started quickly. Its compact design is easy to carry and store, and all key buttons have been carefully laid out to reduce the risk of accidental touch. In addition, the built-in security mechanism can also prevent accidents, so that users can use more confidently.

Whether you are a technician who needs regular vehicle maintenance or a front-line worker who must solve problems quickly in the face of emergencies, this equipment can save you valuable time and reduce labor intensity.

Next, let's take a look at some specific application scenarios! At the construction site of a busy urban subway station, engineers successfully completed the fastening of large rail joints with this high-pressure hydraulic manual compressor, while in another remote mountain bridge construction project, the same device was used to achieve seamless docking between dozens of meters of steel pipes. These real cases fully demonstrate the wide adaptability and excellent performance of the product.

Every environment has different challenges to overcome, but with precise design concepts and the spirit of technological innovation, our products are always at the forefront of the industry.

Of course, there are also long-term factors to consider before choosing the right equipment-such as whether the quality is strong enough to last? Of course, the answer is yes! All components are made of high-quality steel and have passed a rigorous testing process before they are put into the market. This means that even after years of frequent use, the initial good condition can be maintained without being easily damaged.

Therefore, if you are looking for a good helper who can be trusted and accompany your entire career, please do not hesitate to add to the shopping cart list immediately ~

Finally, we cannot ignore the cost-benefit issue. Although the initial purchase cost may be relatively high, overall it actually brings more profit margin to the enterprise due to the reduction of downtime and the extension of service life. Assuming that the working time saved every day is converted into monetary value by hourly wage and multiplied by the number of days in the whole year, it is definitely a considerable amount!

To sum up, investing in such an advanced high-pressure hydraulic manual compressor is undoubtedly one of the best ways to express confidence in future development.

With the continuous development and progress of science and technology, people have put forward new requirements for higher efficiency and lower consumption. It is expected that the high-pressure hydraulic related fields will continue to show rapid growth in the next few years, especially in the new energy vehicle manufacturing and intelligent logistics warehousing and other industries.

Take action now! Let's welcome our own new era together!