Efficient and reliable hydraulic manual compressors: a high-pressure solution for construction machinery

With the progress of engineering technology, the demand for construction machinery is also increasing. Especially in the high-intensity, high-load working environment, the performance of the hydraulic system is particularly important. Today we are going to discuss one of the key technologies- High-pressure hydraulic manual compressor , how does it become a right-hand man in the engineering field?

Why is high-voltage technology so important? The answer lies in its stability and precise control. Compared with ordinary hydraulic systems, high-pressure design can significantly improve work efficiency and reduce energy consumption. This is one of the goals pursued by modern construction projects.

According to the specific needs of construction machinery, this compressor has been optimized and improved. First of all, it is reflected in the strong durability, made of high quality materials, even in the face of bad weather conditions can maintain normal operation; secondly, the ease of operation has been greatly improved, even novice users can quickly master the use method.

Let's look at some real cases! In a large bridge construction project, due to the remote location and complex terrain, the traditional electric drive equipment can not meet the site requirements. However, after the introduction of this high-pressure hydraulic manual compressor unit, it not only solved the energy supply problem, but also greatly shortened the construction period and won unanimous praise from customers.

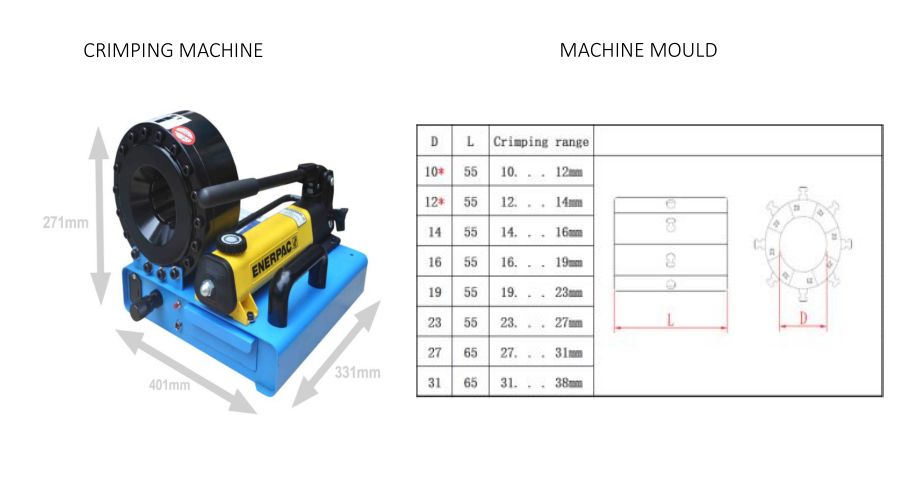

It is also worth mentioning the portable nature of the product. Despite its powerful power output, it is compact and lightweight, making it easy to transport and switch between locations. At the same time, with the modular design concept, the repair work can be completed only by replacing the corresponding parts during maintenance and repair, further reducing the downtime waiting cost.

So what do we need to pay attention to when we are going to buy such a compressor? The first is to clarify the parameters of specific application scenarios such as the maximum pressure value range and other information; the second is the brand reputation and after-sales service guarantee system Whether it is perfect and reliable, etc., need to be carefully considered and weighed before making a decision.

Looking to the future, hydraulic technology will continue to move towards intelligent direction. Functions such as monitoring operating conditions through integrated sensors and automatically adjusting settings to achieve the best results will become more and more popular. I believe that with the passage of time these advanced technology will bring more surprise changes!

All in all, high-pressure hydraulic manual compressors have become an irreplaceable part of modern engineering construction. Whether it is to deal with extreme environmental challenges or the pursuit of the ultimate performance ratio has demonstrated outstanding strength. If you're looking for a professional-grade tool that's both rugged and flexible, be sure to consider adding it to your equipment list.