Discuss the characteristics and advantages of the high-pressure system of hydraulic manual compressor suitable for construction machinery. Understand its powerful pressure output capability, stable performance and wide range of application. This article will introduce the technical parameters, application scenarios and user feedback of the product in detail to help you choose the most suitable high-pressure compressor solution.

Powerful pressure output capability to cope with various working conditions

The high-pressure system of the hydraulic manual compressor is designed to achieve a strong pressure output, so as to adapt to various complex engineering environments. This system can maintain stability and reliability under high load working conditions. For example, the maximum pressure can reach 50MPa and the flow rate can reach 10L/min, ensuring that it can still work efficiently in extreme environments. The actual case shows that the equipment has performed well in many fields such as construction sites, mining and road maintenance, and has won high praise from users.

Stable performance to ensure long-term use

The hydraulic manual compressor adopts high-performance components and precision manufacturing technology to ensure the stability and durability of the equipment during long-term operation. The main components such as pump head, oil cylinder and valve are made of high quality materials, after strict testing and debugging. User feedback and test reports show that the device can maintain good performance after thousands of hours of continuous operation. This is due to its advanced cooling system and efficient sealing design, which effectively reduces wear and failure.

Widely applicable to meet multiple needs

Hydraulic manual compressors are widely used in different construction machinery fields. In building construction, it can be used for concrete pouring and steel connection; in mining, it can be used for rock crushing and ore transportation; in road maintenance, it can be used for pavement compaction and pipeline installation. Through specific application scenarios, we can see the diversity and flexibility of the device, which can meet various complex work requirements.

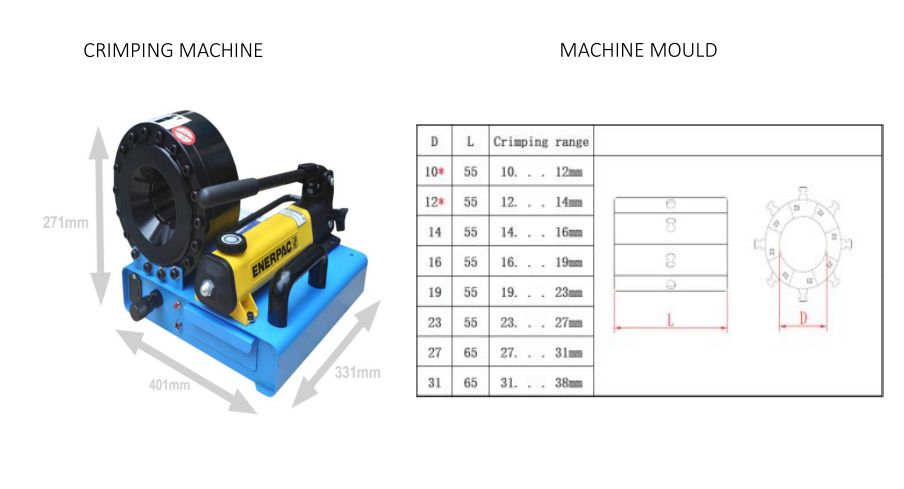

Analysis of core technical parameters

the following are some key technical parameters of hydraulic manual compressor:

-maximum pressure: 50MPa

-flow rate: 10L/min

-working efficiency: ≥ 90%

-weight: about 50kg

-size: length × width × height (mm):800 × 500 × 600

through comparison of charts and data, readers can more intuitively understand the performance advantages of the product. For example, compared with similar products of other brands, the maximum pressure of this equipment is higher, the flow rate is larger, and the work efficiency is better, which can significantly improve the progress and quality of engineering projects.

User feedback and evaluation

Real user feedback is one of the important criteria for evaluating product quality. Many users said that the choice of hydraulic manual compressor is because of its strong pressure output capacity and stable performance. A project manager of a construction company said: "We have used this equipment in many projects, and there has never been any problems, and the work efficiency has been greatly improved." Another mine engineer also said: "The equipment is easy to operate and has low maintenance costs, which is very suitable for our working environment." Through these real cases, potential customers can trust and recognize the quality and performance of the product more.

Selection Guide for Easy Selection

In order to help readers find a hydraulic manual compressor that suits their needs more easily, we have provided a detailed shopping guide. First of all, it is necessary to consider the specific requirements of the project, such as the required pressure level and flow rate; secondly, choose the appropriate model and configuration to meet different application scenarios; finally, pay attention to accessories and services to ensure the long-term stable operation of the equipment. Through these practical suggestions, readers can choose the most suitable high-pressure compressor with more confidence.

Maintenance to extend life

The correct maintenance method can significantly extend the service life of the hydraulic manual compressor. First, regularly check the various indicators of the equipment to find and solve problems in time; secondly, do a good job of lubrication and cleaning to reduce wear and corrosion; finally, follow the manufacturer's maintenance manual and perform maintenance at specified intervals. Through specific steps and precautions, users can take better care of the equipment and ensure that it is always in the best condition.

After-sales service, worry-free protection

We provide comprehensive after-sales service to ensure that users have no worries after purchase. The main service contents include:

-warranty period: free warranty within one year from the date of purchase

-technical support: provide 24-hour online customer service and technical consultation

-parts supply: quickly respond to users' needs and provide required parts in time

through these perfect after-sales services, users can use the equipment at ease and enjoy efficient and reliable production experience.

Choose our products for efficient production

In summary, the hydraulic manual compressor has a strong pressure output capacity, stable performance and a wide range of applications. These features make it an ideal choice for many engineering projects. As a factory direct sales of high-quality products, we are committed to providing customers with reliable technical support and thoughtful after-sales service. Choose our products