Reveal the high-performance core: the working principle of high-pressure hydraulic manual compressor

As one of the important tools in the field of modern engineering, the high-pressure hydraulic manual compressor has become the first choice for many enterprises with its unique technical advantages. It uses the principle of high-pressure hydraulic system to achieve efficient energy transmission and power output through pressure conversion.

Compared with traditional pneumatic or electric compression devices, high-pressure hydraulic manual compressors have higher accuracy and stronger power transmission capabilities. For example, in the practice of a bridge construction project, a high-pressure hydraulic manual compressor successfully completed the precise docking task of hundreds of tons of steel beams, fully demonstrating its strong performance potential.

Stability beyond expectations: Why this compressor?

In addition to excellent performance, this high-pressure hydraulic manual compressor also has extremely high stability and durability. Thanks to the application of high-quality materials and the support of exquisite manufacturing technology, stable operation can be maintained even in extreme weather conditions.

Statistics show that the average life span of such equipment can reach more than ten years, and the probability of failure during the entire life cycle is less than 5. Such excellent performance saves users a lot of maintenance costs and time costs.

From theory to actual combat: detailed explanation of typical application scenarios

High-pressure hydraulic manual compressors are widely used in various types of engineering construction, especially in the case of heavy load operation. For example, in the process of tunnel excavation, it can be used to drive large drilling equipment; and in the ship repair factory, it is responsible for completing the tight connection process between the hull steel plates.

Each specific application has a corresponding implementation plan for reference. Taking the laying of oil pipelines as an example, technicians will first determine the required pressure level, and then configure the appropriate accessory components according to the actual situation, so as to ensure that every operation can be successfully completed.

How to choose the best high-pressure hydraulic manual compressor for you?

Faced with the dazzling array of brand models on the market, consumers are often confused. At this point, a series of professional indicators are needed to make judgment choices.

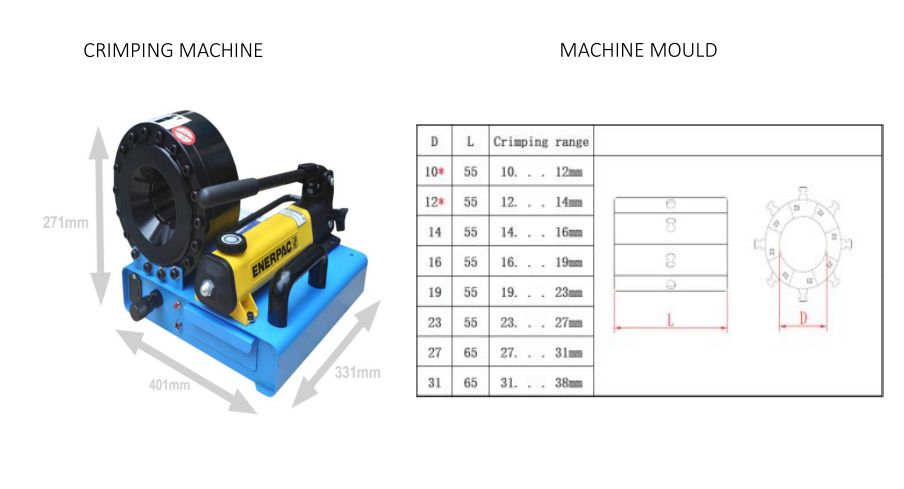

The first is the choice of power size, which depends on the load requirements of the actual work. The second is whether the interface form is compatible with the existing facility system. There is also whether the price range can match the budget range and other aspects need to be comprehensively considered to make a decision after weighing the pros and cons.

Future trend outlook: What will the next generation of high-pressure hydraulic manual compressors look like?

With the continuous development of science and technology, we can foresee that the future of high-pressure hydraulic manual compressors will become more intelligent and green. Intelligent control systems will give them self-diagnosis and repair functions, greatly reducing the frequency of human intervention; and new renewable energy to replace fossil fuels, is expected to achieve the goal of zero emissions.