Efficient working partner: high-pressure hydraulic manual compressor for construction machinery

In the field of modern engineering construction, a reliable tool can often determine the efficiency and quality of work. Today, I would like to introduce to you such a "right-hand man"-a high-pressure hydraulic manual compressor designed for all kinds of construction machinery.

Why does this high-pressure hydraulic manual compressor become a necessary tool in the engineering field? The answer lies in its excellent performance and wide range of application. For tasks that require high-intensity pressure support, this device is undoubtedly one of the first choices. With excellent stability and precise operation experience, it can easily cope with various complex construction conditions, thereby greatly improving work efficiency.

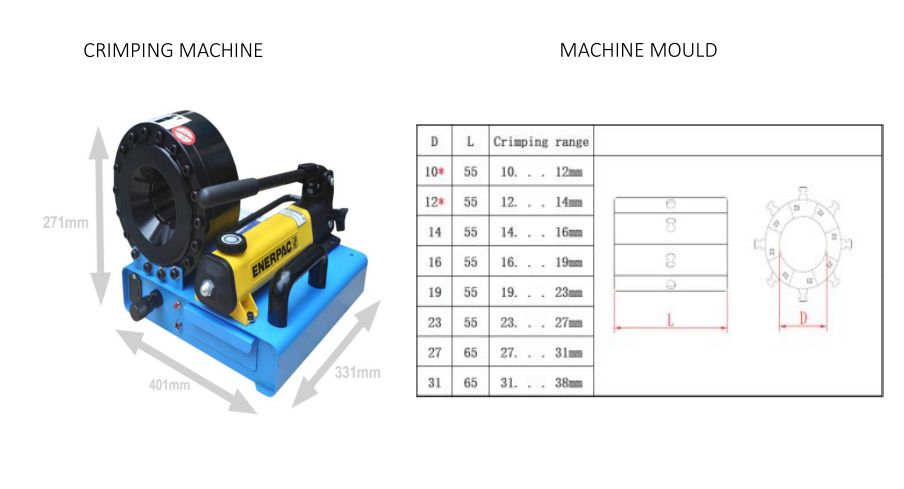

In-depth analysis of the core benefits of this product, you will find many amazing technical details hidden in it. The first is the ability to perform under unhurried pressure, even in the face of extremely demanding work scenes; the second is the extremely excellent durability, the sturdy material and the carefully polished design process enable it to serve in harsh environments for a long time without losing standards. In addition, there are light and flexible features, convenient carrying and transportation, simple and easy-to-understand operation process, which reduces learning costs and other advantages, which jointly create the image of this powerful industrial helper.

In order to make everyone feel the power of this compressor more intuitively, we will share it through several real cases. In a road rehabilitation project in a remote mountainous area, traditional power tools cannot be used normally due to the complex terrain and lack of power supply. At this time, the engineering team chose our high-pressure hydraulic manual compressor as the solution and successfully completed all tasks within the predetermined plan. Another example occurs at a large construction site, where a large number of heavy machinery is often used to dismantle and reorganize, and other work steps are cumbersome and time-consuming. However, since the introduction of this system, it has not only accelerated progress but also reduced the probability of human error and significantly improved the overall level of revenue.

Of course, in addition to the above-mentioned applications, this type of compressor can also be widely used in daily maintenance, such as car tire inflation adjustment, pipe seal testing and other similar occasions are very suitable for demand. Especially in some special cases (such as emergency rescue operations), the advantage of its strong independence without relying on external energy supply is even more precious.

finally, it enters the guidance part of the purchase stage. considering the wide variety and different specifications of similar products in the market, it is especially important to make clear your specific use requirements before purchasing. For example, if you mainly aim at outdoor activities, you should give priority to the problem of battery life. If it is installed in a fixed place in an indoor workshop, factors such as size, weight and so on also need to be taken into consideration! In a word, as long as the corresponding parameter standards are reasonably matched according to the actual situation, you can buy the most suitable machine ~