In-depth discussion of the characteristics and advantages of high-pressure hydraulic manual compressors suitable for construction machinery, analysis of its application examples in complex construction environments, and how to choose the right model to improve work efficiency and safety. This article aims to provide professional users with comprehensive product information and technical guidance.

Application field of high-pressure hydraulic manual compressor

Essential Tools for Construction Sites

High-pressure hydraulic manual compressors are widely used in construction sites. Whether it is steel connection, pipeline repair, or other heavy-duty operations, they can provide reliable performance. Its strong pressure output and stable operation ability ensure the quality and progress of construction.

Key equipment for mining

In mining, high-pressure hydraulic manual compressors play a vital role. It can operate stably in harsh environments and provide efficient compressed air to ensure the smooth progress of mining operations. Its sturdy construction and durable materials enable it to work for long hours under extreme conditions.

Efficient assistant in bridge construction

High-pressure hydraulic manual compressors also have excellent performance in bridge construction, especially in the installation of prestressed anchoring systems. It can provide accurate high-voltage output to ensure the stability and reliability of the anchoring system. Its compact and lightweight design allows it to operate flexibly in narrow spaces.

Core features of high-pressure hydraulic manual compressors

Powerful pressure output

High-pressure hydraulic manual compressors have a strong pressure output capacity up to several hundred bar. This allows it to meet the needs of heavy-duty operations, whether it is steel connection, pipe repair, or other high-intensity tasks, it can easily handle to ensure construction quality and progress.

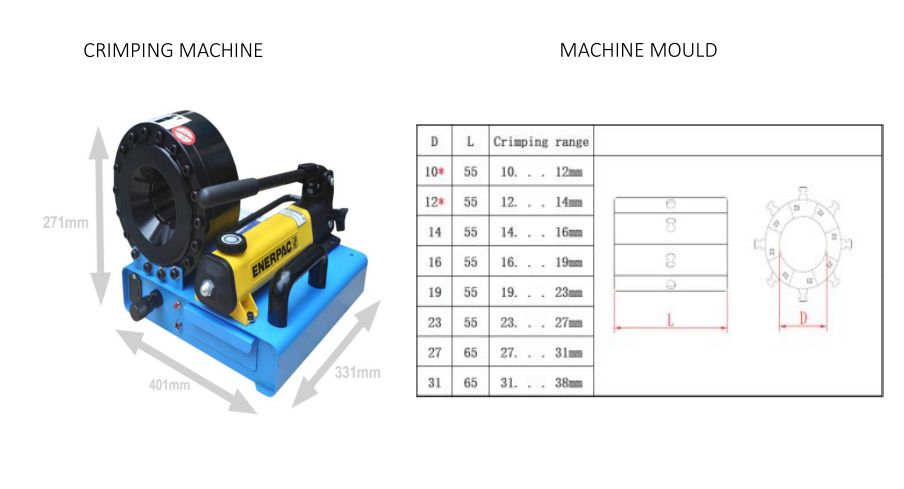

Compact and lightweight design

Despite its powerful performance, the high-pressure hydraulic manual compressor uses a compact and lightweight design. Its small size, light weight, easy to carry and operate, very suitable for use in a small space. This design makes it flexible in different construction site conditions.

Easy-to-maintain structure

The high-pressure hydraulic manual compressor adopts a modular design, and the disassembly and assembly between the components are simple, which greatly simplifies the maintenance and overhaul work. This design not only reduces operating costs, but also extends the service life of the equipment. Users can quickly replace damaged parts to ensure that the equipment is always in the best condition.

Guide to choosing the right model

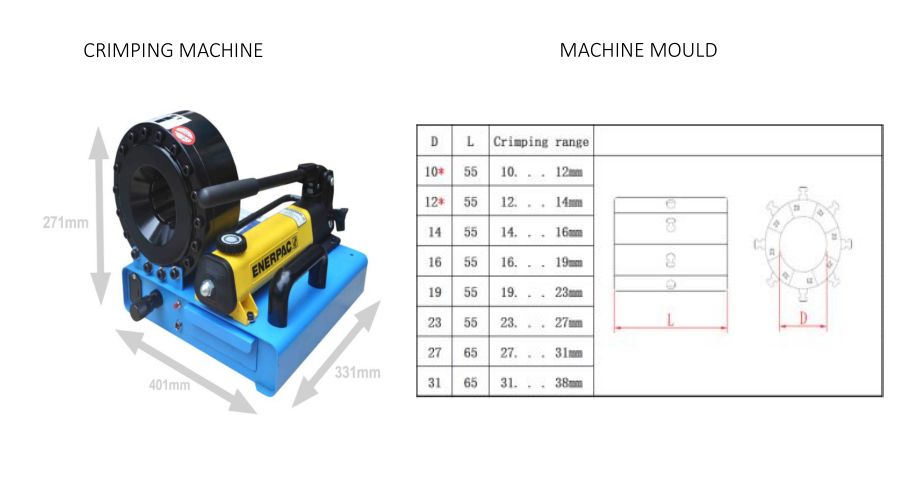

Determine the required pressure level

When selecting a high-pressure hydraulic manual compressor, first determine the minimum pressure level required. Different construction tasks have different requirements for pressure, so it is very important to choose the appropriate pressure level. Too high or too low pressure will affect the construction effect, and even cause equipment damage. It is recommended that users consult professional technicians and choose the appropriate model according to specific needs.

Assess the requirements of the operating environment

Different construction sites have different requirements for equipment. When choosing a high-pressure hydraulic manual compressor, you need to consider the specific conditions of the site, such as space constraints and power supply. If the construction site space is small, you can choose a smaller model; if the power supply is unstable, you can choose a battery-powered model. A comprehensive assessment of these factors can help users choose the most appropriate device.

Consider brand and service support

It is wise to choose a well-known brand of high-pressure hydraulic manual compressor. Well-known brands usually have higher product quality and better service system. Users can judge the reputation and strength of the brand by viewing the history of the brand, user evaluation and technical support. In addition, high-quality after-sales service is also an important guarantee to ensure the long-term stable operation of the equipment.

Practical Application Case Study

Successful experience of a large construction project

In a large construction project, the high-pressure hydraulic manual compressor played an important role. The project involves the rebar connection and pipe repair tasks of multiple high-rise buildings, and the performance requirements of the equipment are very high. By using high-pressure hydraulic manual compressors, the construction team not only improved work efficiency, but also ensured project quality. In the face of complex construction environment and tight construction period, the equipment shows excellent performance and stability.

Efficient use in mining

In a mining project, high-pressure hydraulic manual compressors are widely used in drilling and crushing operations. Due to the harsh mine environment, the equipment must have a high degree of reliability and durability. With its strong pressure output and stable operation ability, the high-pressure hydraulic manual compressor not only improves production efficiency, but also ensures the safety of staff. The project leader said that the equipment